+86-510-88852188 sales@bdctec.cn frank.guo@bdctec.cn

ABOUT US

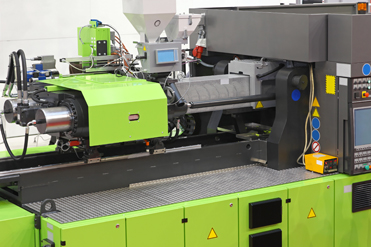

BDC Focus on Industrial Damping Technology. BDC is a premier supplier of engineered Mechanical Shock Absorbers, Deceleration Devices and products for Hydraulic/Pneumatic Actuation and Motion Control applications. Our products and services can be found in use throughout the global Industrial, Rail and Transportation, Automation and Infrastructure markets. BDCs highly engineered critical components and customized technology solutions to stay at the forefront of new technologies, six-sigma and lean manufacturing research and development provide the low cost and high quality products for our custom...

VIEW ALLTop